Anti-Reflective Glass

VISION-LITE

Anti-reflective coated glass significantly reduces the reflection of light on the surface of the glass.

VISION-LITE anti-reflective coated glass significantly reduces the reflection of light on the surface of the glass. To achieve the anti-reflective effect, the glass must be coated on both faces.

VISION-LITE is available in STADIP PROTECT laminated glazing, produced from DIAMANT extra-clear glass. The low-reflective coating is on both faces of the laminated pane of glass.

Various thicknesses are possible from laminating together the base glass which comes in 4mm, 6mm, 8mm 10mm. e.g. 8.8mm, 12.8mm, 16.8mm and 20.8mm.

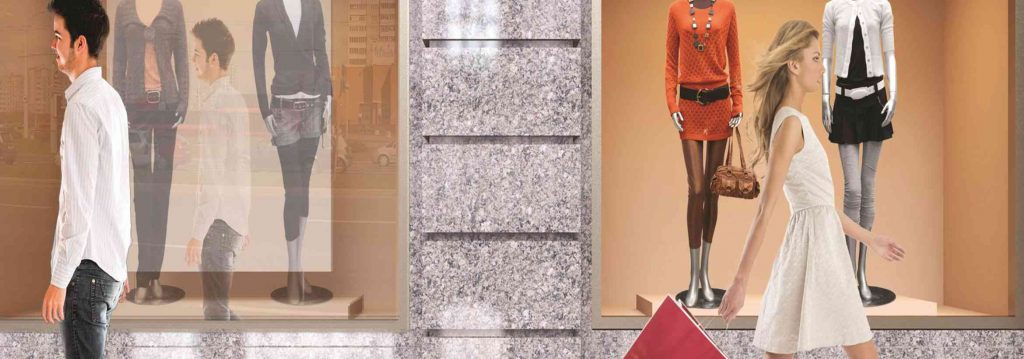

VISION-LITE is ideal for all applications that require maximum transparency and unimpaired vision through the glass.

External:

- Shop fronts and show rooms;

- Glazed areas in panoramic restaurants;

- Control towers, control rooms and observation rooms;

- Screens to separate spectators in terraced stadiums.

Internal:

- Display cabinets in museums and protective screens for paintings;

- Display units and shop fronts;

- Internal partitions (hospitals, clean rooms, control rooms, etc.);

- Television studios (less reflection in front of the cameras);

- Interpreter booths and sound booths (conference rooms, recording studios, etc.);

- Zoos and aquariums.

Other applications:

- Machine control rooms on building sites (cranes, tractors, etc);

- Protective screens for cash dispensers;

- Signage or advertising panels for railways, motorways and airports, etc.

There are many benefits of using VISION-LITE:

- Optimum vision: very high transparency levels and very low residual reflectance (approximately 8 times less reflection than conventional glass) for improved visibility.

- Clarity of objects: better contrast and colour rendering.

- UV reduction: VISION-LITE blocks out over 99% of the sun’s UV rays, reducing the discolouration of items exposed to direct sunlight.

- Large sizes: available in large dimensions for shop fronts or showroom windows.

- Safety: VISION-LITE is available as STADIP PROTECT laminated safety glass for enhanced security.

Performance comparison between PLANICLEAR conventional glass and VISION-LITE anti-reflective glass.

| Thickness | Light transmittance LT % | Light reflective LRe % | |

| PLANICLEAR | 8.8 | 87 | 8 |

| VISION-LITE* | 8.8 | 96 | 1 |

| PLANICLEAR | 12.8 | 85 | 8 |

| VISION-LITE* | 12.8 | 96 | 1 |

| PLANICLEAR | 16.8 | 83 | 8 |

| VISION-LITE* | 16.8 | 95 | 1 |

| PLANICLEAR | 20.8 | 83 | 8 |

| VISION-LITE* | 20.8 | 95 | 1 |

* On DIAMANT glass Values given in accordance with standard EN410. The reflectance values are measured perpendicular to the glazing. As with conventional glass, the reflection increases when the glass is viewed from an angle.

VISION-LITE meets the durability requirements of Class A of European standard EN1096.

Important

The residual reflectance of VISION-LITE anti-reflective glass is very low (approximately 1% for laminated monolithic glass). It is however still visible under certain lighting conditions, viewing angles and in certain surrounding environments. The residual reflectance depends on the angle from which it is viewed. Perpendicular to the glass, it is slightly bluish and can vary slightly. For external applications (eg: shop fronts), it is strongly recommended that a sample is viewed in the intended location.

VISION-LITE is a coated glass which is treated on both sides. It must be processed and installed in accordance with specific instructions.

VISION-LITE coated glass cannot be heat-treated, i.e. toughened or heat-strengthened.

For roof applications, it is not recommended to position the anti-reflective coating facing towards the outside (face 1).

For horizontal interior applications (museum display cabinets, shelves, tables etc), precautions must be taken to avoid frequent and excessive finger marks and the risk of scratching.